Neurophotometrics

Benefits

14,500

Printer hours

17

Unique 3D printed parts

7

Markforged carbon fiber printers

The Customer

The scientific hardware industry has long been an expensive one to participate in, leading to costly, outdated equipment. Neurophotometrics, based in California, designed a device that uses optical tools to record brain activity from a freely moving animal.

The Challenge

Sage Aronson, CEO and Founder of Neurophotometrics, wanted to ensure his device could be entirely customizable and accessible for scientists around the world, but this was not an option with traditional manufacturing methods. “Our longer term goal is to disrupt the scientific hardware industry,” says Aronson.

"We wouldn’t have a company if we couldn’t print it [the device]. It wouldn’t be possible to do, and it wouldn’t be possible to do on our small scale."

— Sage Aronson, CEO and Founder, Neurophotometrics

The Solution

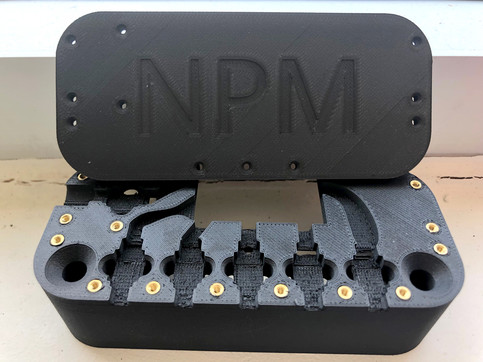

Aronson realized the only way he could fabricate his device affordably was to utilize a 3D printer. He had heard about Markforged from a friend, and decided to get a benchmark part made. After finding the material to be strong enough for his device, he purchased a Markforged desktop 3D printer to create hardware components for the device. The team iterated through dozens of prototypes, yielding a functioning prototype in just three months. Aronson bought six more Markforged desktop printers to keep up with the demand for his product, and started to create 3D printed end-use components. “If we weren’t able to print and use parts with this, the business wouldn’t have started,” Aronson says. Markforged printers allow Aronson and his team to create parts with precision that can easily interact with delicate and expensive optical instruments without scratching or breaking them.

The most significant and the largest of these parts is the optical housing for the device — a single piece that holds all the optical instruments with a high degree of precision. The entire component takes just over two days to print, and costs a little over $50 in material. The optical housing isn’t the only production part printed on his Markforged printers. Aronson estimates that around 90% of the printers’ usage is printing end-use parts for the device, with 17 parts fabricated on the printer and three structural metal parts traditionally manufactured. “Really this is a 3D printed system with a few metal parts,” says Aronson. Neurophotometrics has been able to compete with giant companies by changing the price point of scientific hardware — all thanks to additive manufacturing. In the first two years of operation, Aronson estimates Neurophotometrics has over 14,500 printer hours and has gone through over 100 spools of filament.

"The thing I’ve been most impressed with is just how bullet-proof the system is. We use these printers pretty heavily with no issues."

— Sage Aronson, CEO and Founder, Neurophotometrics

The Future

Neurophotometrics currently has their devices in several companies around the world. The team has become more versatile and has shipped their product across 10 countries, including the United States, Canada, Germany, South Korea, and Australia, and have recently introduced their first Japanese distributor. Aronson expects to add several more Markforged printers to his print farm to keep up with growing demand, and says Markforged will continue to play a central part in his business.

Markforged Partner

Superior 3D Solutions

所有博客和博客中包含的信息版权均归 Markforged 公司所有,未经我们的书面许可,不得以任何方式复制、修改或采用。我们的博客可能包含我们的服务标志或商标,以及我们附属公司的服务标志或商标。未经我们事先许可,您使用我们的博客并不构成您使用我们的服务标记或商标的任何权利或许可。Markforged 博客中提供的信息不应被视为专业建议。我们没有义务根据新信息、后续事件或其他情况更新或修订博客。

不错过任何一篇文章

订阅以在您的收件箱中获取新的 Markforged 内容