Markforged Resources

Blog

Learn

Blog

The Evolution of Metal Parts Manufacturing: A Factory Floor Perspective

Metal parts manufacturing is evolving fast—from casting to CNC to 3D printing. Discover how engineers and production teams can meet today’s demands with safer, faster, and more flexible workflows using metal additive technologies like the FX10 and PX100.

Learn

Blog

Food Safe 3D Printer Filament: From Compliance to Customization

Strict regulations have limited 3D printing in food & beverage—until now. Learn what makes a filament food safe, where it fits on the factory floor, and how certified materials are unlocking new manufacturing possibilities.

Learn

Blog

Introducing Nylon White FS: Expanding 3D Printing for Food and Beverage Factory Floors

Learn about our new food-contact certified material designed specifically for the food and beverage factory floor.

Learn

Blog

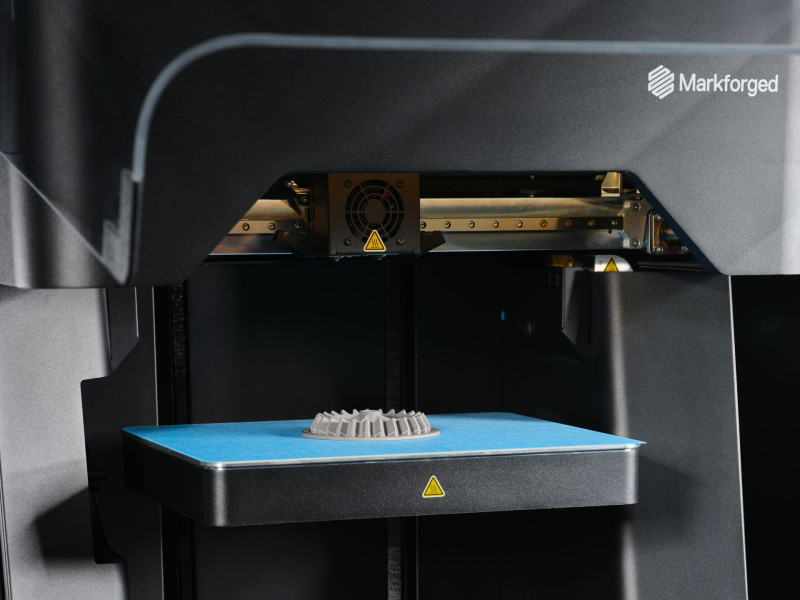

Meet the FX10: The First Industrial Metal and Composite 3D Printer

In Fall 2023, we launched FX10 as a next generation composite printer. We promised modularity, but didn’t specify what modularity meant. Now, we can clarify. The modularity we were promising was Metal FFF capability – making FX10 the first industrial printer capable of printing composite and metal parts.

Learn

Blog

Enhancing Packaging Machine Builders' Efficiency with Custom Additive Manufacturing Solutions

Additive manufacturing has emerged as a powerful tool to meet the challenges facing machine builders in food and beverage packaging.

Learn

Blog

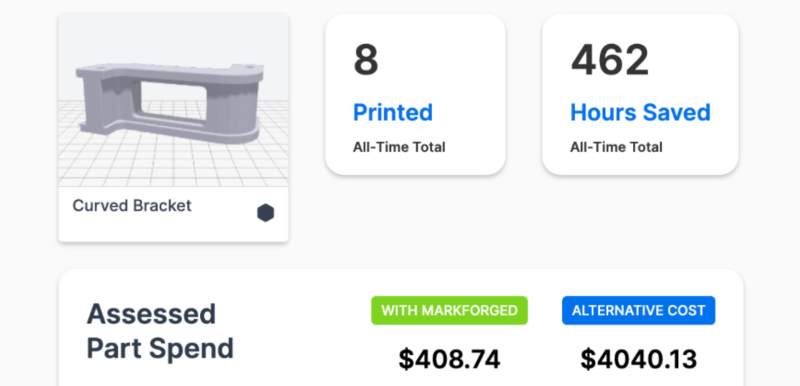

Reliably Measure Savings with Expanded ROI Tools in Eiger

New tools in the ROI Dashboard allow you to enter known part costs and details, providing a more realistic estimate of actual savings that you can use when making data-driven decisions for your business.

Learn

Blog

Customer Success Stories

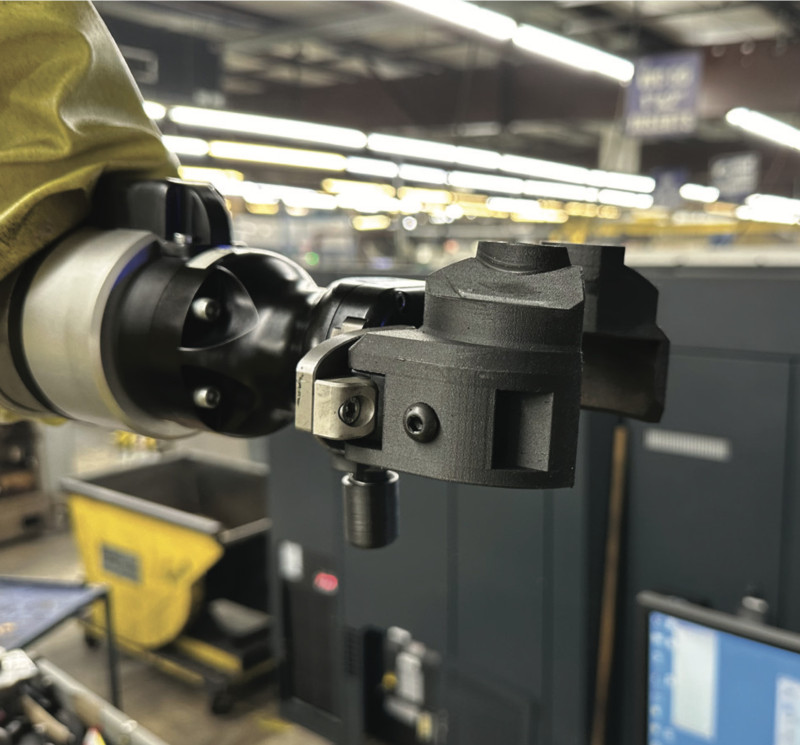

Dixie Iron Works/MSI

Markforged industrial 3D printers have significantly enhanced Dixie Iron Works' manufacturing capabilities, enabling rapid and cost-effective production of high-quality parts. The adoption of printers like the X7 and Metal X has reduced production costs and minimized the need for extensive CNC machine setups. These advancements have improved Dixie Iron Works' ROI by lowering material costs and allowing for the efficient in-house production of customized components.

Learn

Blog

Robotics in the Food Industry: Solving Manufacturing Problems with Automation

The food and beverage industry faces numerous challenges that have intensified in recent years. Key issues such as maintaining a reliable workforce, ensuring safety and efficiency, and adapting to ever-changing market demands have pushed the industry towards innovative solutions. Robotics in the food industry, coupled with advances in additive manufacturing technology, are emerging as game-changers in this landscape.

Learn

Blog

Customer Success Stories

SQP Engineering and Strada Percussion Drilling Systems

Discover how SQP Engineering and Strada Percussion Drilling Systems improved the accuracy and efficiency of measuring drill bit wear with Markforged's FX20™ and Onyx® material. By designing and 3D printing precision gauging calipers, they reduced tooling costs by 30% and cut lead time from 2 weeks to 2 days.

Learn

Blog

Application Spotlights

SQP Engineering

Learn how SQP Engineering optimized their CNC production with Markforged's FX20™ and Onyx® material by creating cost-effective vacuum part holding jigs. This innovative solution significantly reduced tooling costs and enhanced productivity, leading to increased revenue.