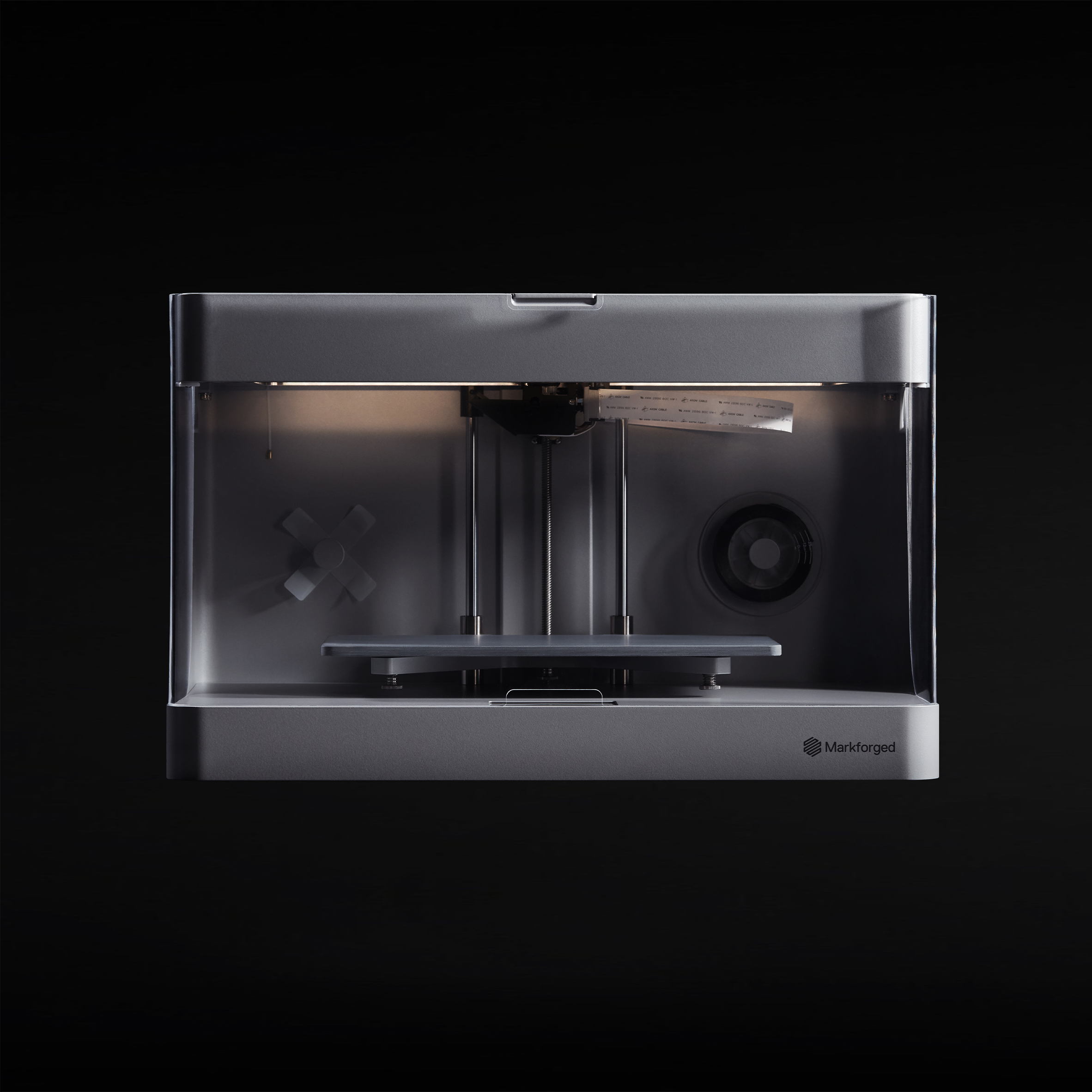

Mark Two™

Composite Parts

3D Printer

Physical Dimensions

Build Volume

Z Layer Resolution

100 μm - 250 μmPrinting Media

Composite Base Filaments, Continuous FibersInternal Part Geometry

Closed Cell Infill with Continuous Fiber ReinforcementPrint Bed

Precision Ground CompositePrinting Process

Continuous Fiber Reinforcement (CFR)

Materials

Compatible Materials

System Details

About the Mark Two

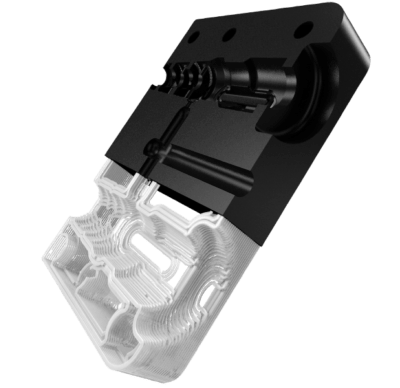

The Mark Two is the award winning professional carbon fiber composite 3D printer – built around the Continuous Fiber Reinforcement (CFR) process to reliably produce strong parts for you. It’s built around an aluminum unibody frame that delivers high accuracy and repeatability. A hardened extrusion system enables the Mark Two to print Onyx — a micro carbon fiber filled nylon filament that destroys traditional extrusion systems — reliably over thousands of print hours. The machine is built to be easy to operate and maintain — from easy-to-reach wear components (like nozzles and feed tubes) to usability focused features like the print bed, which can be removed and replaced with 10 μm repeatability.

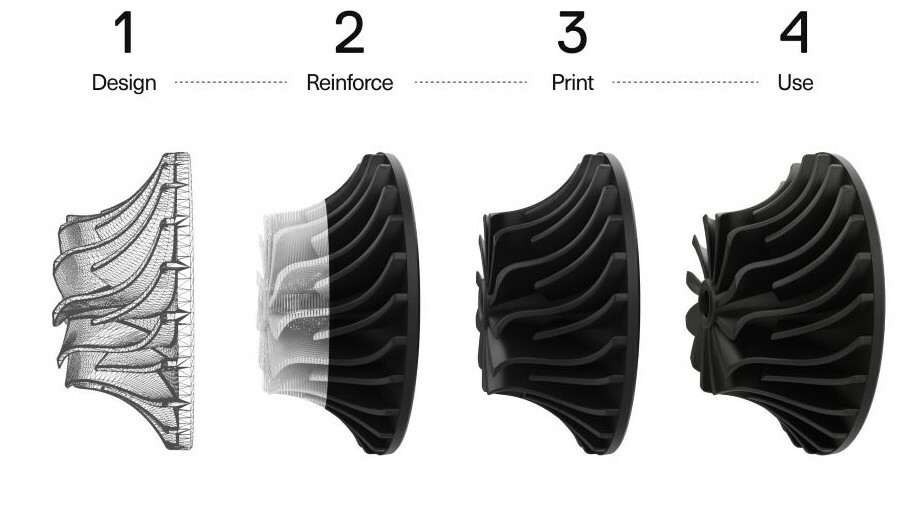

In addition to more common FFF features, the Mark Two has a 2nd-generation fiber reinforcement system that enables you to lay down continuous fiber into parts. Markforged composite printers are capable of printing continuous fiber reinforced parts, which can be as strong as machined aluminum.

Mark Two™ Materials

- Learn More

- Learn More

- Learn More

- Learn More

- Learn More

- Learn More

- Learn More

- Learn More

Continuous Fiber Reinforcement, Made Easy.

Request a Quote